Turbo™ Multi-layer Cutter

Designed for cutting through multiple layers of steel in one fast, clean operation.

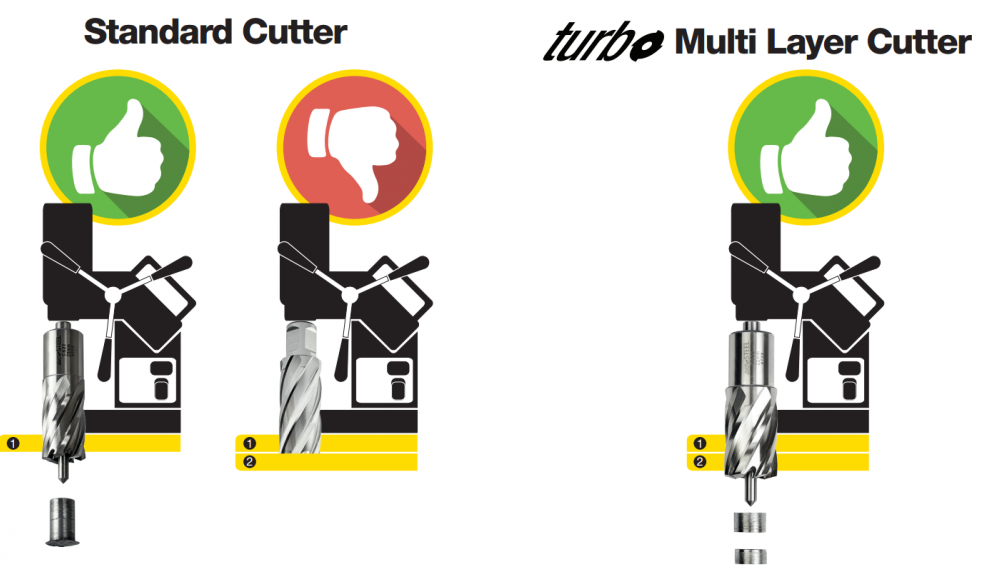

Standard annular cutters are only designed to cut though one solid plate before ejecting the solid slug. The Turbo Multi-layer cutter solves that by enabling multiple layers of steel in clean cut.

- Reduces tool breakages – no need to stop and start the whole process.

- Increases productivity – achieve the hole in one cut.

- Ideal for removing existing bolts from old steel structures and bridge refurbishment.

- Use on site work when needing to bolt together two sections of steel.

- Available as an option on all types of Turbo annular cutters.

Why the Turbo™ Multi-layer Cutter Cutters?

Also referred to as “Laminate”, “ID” or “Stack” drilling, the Turbo multi-layer cutter features a special cutting tooth form that will retract the multiple slugs in the cutter, to be ejected together at the end of the cut.

Efficient and hassle-free

- Reduces tool breakages – no need to stop and start the whole process

- Increases productivity – achieve the hole in one cut

- Ideal for removing existing bolts from old steel structures and bridge refurbishment

- Use on site work when needing to bolt together two sections of steel

- Available as an option on all types of Turbo annular cutters

Can't find the size you require? Get in touch.

We can manufacture a range of cutters and machines to suit your requirement. No matter your requirement, contact us today and speak to our specialist team.

Contact Us