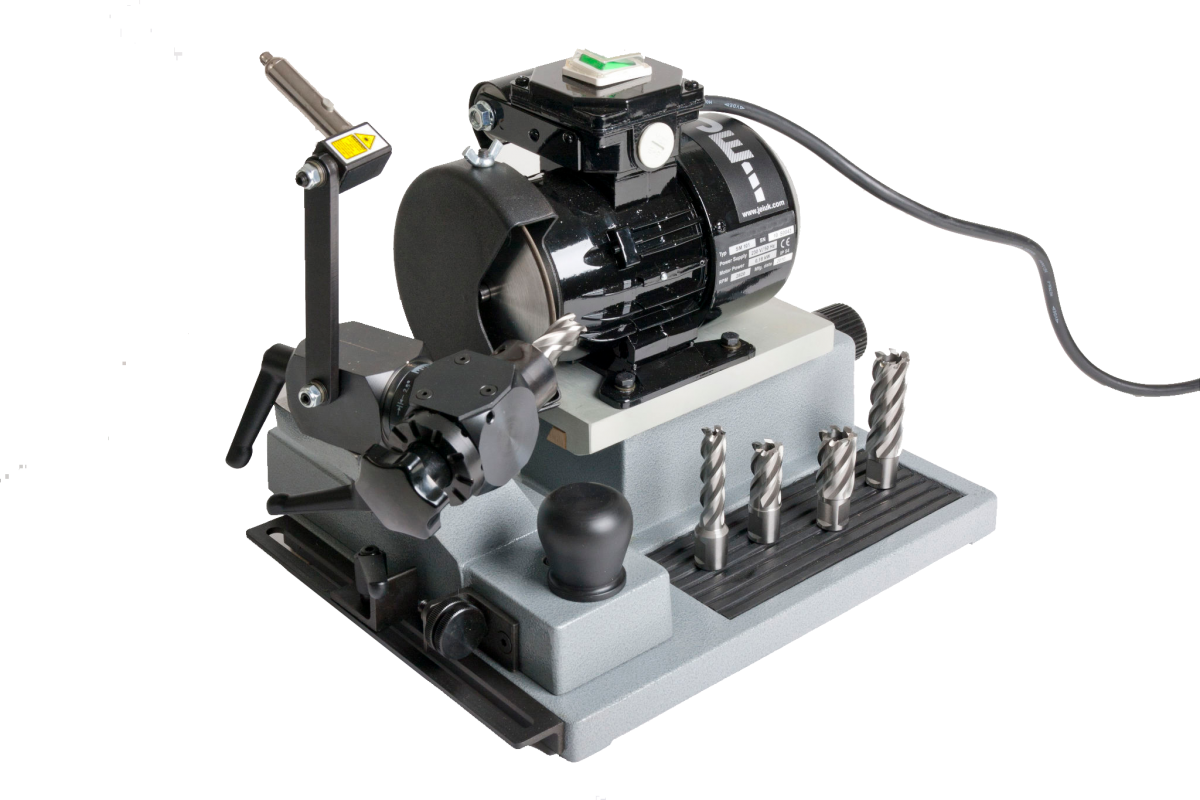

Annular Cutter Regrinding Machine

A simple, easy to use machine, specifically designed for quality annular cutter regrinding.

Saves time and money in carrying out an effective cutter regrind, particularly if the customer is in urgent need of continued production drilling.

- Simple set up and operation – Easy positioning of cutting tool.

- Economical – far less expensive than heavier equipment.

- Lightweight and portable – ideal for site work, or a small workshop.

- Diamond wheel – creates a sharp, clean new cutting edge.

- Easy angle adjustment – simple alignment to original angle geometry.

- Laser guided cutter alignment – ensuring correct positioning of cutting edge to the wheel.

- Additional gullet reforming wheel supplied – extending the life of the annular cutter.

- Supplied with full range of index plates – to covermost cutter diameters / no. of teeth (HSS type only).

DOWNLOADS:

For use with JEI Turbo Steel or other Brands of HSS annular cutters, with a 19 mm Shank. Will regrind cutters from 12 mm diameter to 50 mm diameter in cutting depths of 1” (25 mm) and 2” (50 mm).

Annular Cutter Regrinding MachineSPECIFICATIONS

| Dimensions L x W x H | 410 x 412 x 390 mm (without optics) |

| Net Weight | 15.5 kg |

| Power supply | 240 Volts, 50 / 60 Hz |

| Motor Power Speed | 0.12 kW, 2,800RPM |

| Noise Level | < 70dB |

| Grinding Disk | Diamond grinding disk, Ø125 mm, Bore Ø10 mm |

| Annular Cutter Holder Shaft Bore | 19 mm (weld on shaft) serial, 32 mm (weld on shaft) optional on request |

Watch our regrinding machine in action

A quick and economical solution to increase the life and productivity of annular broaching cutters used to produce holes in steel. Simple to operate, an ideal support tool for the industry professional.

Learn More

Want to make sure the Annular Cutter Regrinding Machine is right for you? Speak to our specialist solutions team today.